SWC Series

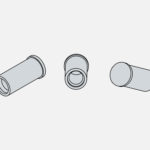

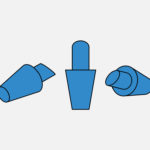

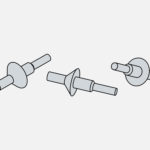

SWC Series – Silicone Washer Caps

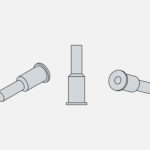

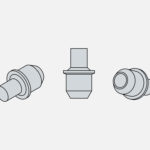

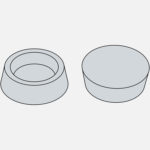

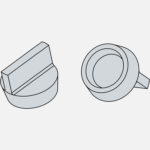

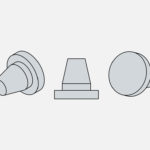

Protecting a piece of equipment means reducing harmful exposure to some of its most vulnerable components. Holes and studs are very susceptible to damage, especially during certain maintenance processes, making it crucial that you do what you can to reduce the impact when possible. SWC Series silicone washer caps mask threaded and non-threaded studs and holes as well as the surrounding grounding area. This unique design more effectively blocks out particulates and moisture since the silicone caps sit flush with the rest of the machine. We recommend them for powder coating, e-coating, anodizing, and plating applications. Silicone washer caps are also very flexible, allowing them to fit a series of different studs with little trouble. Learn more below.

- Color: Natural

- Silicone service temperature: 600˚ F (316˚ C)

- Additional sizes available (consult factory for details)

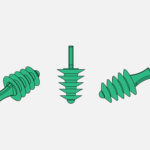

- Additional material available: EPDM

Product Options

Please confirm that your Part Number is correct and adjust the other selections below to meet your application's requirements.

Make Your Selection Below

| PART NO. | COLOR | A | B | C | L | PRODUCT OPTIONS | |

|---|---|---|---|---|---|---|---|

| in. | in. | in. | in. | ||||

| SWC-0100-0500 | Natural | 0.100 | 0.500 | 0.225 | 1 | ||

| SWC-0106-0472 | Natural | 0.106 | 0.472 | 0.244 | 1 | ||

| SWC-0125-0500 | Natural | 0.125 | 0.500 | 0.252 | 1 | ||

| SWC-0140-0500 | Natural | 0.140 | 0.500 | 0.323 | 1 | ||

| SWC-0146-0472 | Natural | 0.146 | 0.472 | 0.260 | 1 | ||

| SWC-0156-0500 | Natural | 0.156 | 0.500 | 0.315 | 1 | ||

| SWC-0172-0500 | Natural | 0.172 | 0.500 | 0.382 | 1 | ||

| SWC-0180-0600 | Natural | 0.180 | 0.600 | 0.315 | 1 | ||

| SWC-0220-0472 | Natural | 0.220 | 0.472 | 0.339 | 0.800 | ||

| SWC-0220-0500 | Natural | 0.220 | 0.590 | 0.358 | 1 | ||

| SWC-0220-0787 | Natural | 0.220 | 0.787 | 0.343 | 1 | ||

| SWC-0223-0720 | Natural | 0.223 | 0.720 | 0.343 | 1 | ||

| SWC-0240-0500 | Natural | 0.240 | 0.500 | 0.358 | 1 | ||

| SWC-0295-0500 | Natural | 0.295 | 0.500 | 0.413 | 1 | ||

| SWC-0295-0700 | Natural | 0.295 | 0.700 | 0.413 | 1 | ||

| SWC-0295-1000 | Natural | 0.295 | 1 | 0.413 | 1 | ||

| SWC-0300-0675 | Natural | 0.300 | 0.675 | 0.417 | 1 | ||

| SWC-0375-0825 | Natural | 0.375 | 0.825 | 0.512 | 1.500 | ||

| SWC-0453-0984 | Natural | 0.453 | 0.984 | 0.650 | 1.500 | ||

| SWC-0460-0700 | Natural | 0.460 | 0.700 | 0.571 | 1 | ||

| SWC-0500-1000 | Natural | 0.500 | 1 | 0.606 | 1 | ||

| SWC-0615-1180 | Natural | 0.615 | 1.180 | 0.815 | 1.500 | ||

| SWC-0750-1250 | Natural | 0.750 | 1.250 | 0.870 | 1.500 | ||

| SWC-0780-1475 | Natural | 0.780 | 1.475 | 0.972 | 1.500 | ||